Struktur

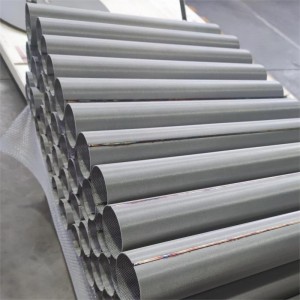

Bahan

DIT 1.4404 / AIS 316L, DIN 1.4539 / AISI 904L

Mononel, baja, duples baja, alloys hastely

Bahan liyane sing kasedhiya ing panyuwunan.

Filterensifikasi Filter: 1 -200 mikik

Ukuran

500mmx1000mm, 1000mmxx1000mm

600mmxxmm, 1200mmxx1200mm

1200mmxx1500mm, 1500mmx2mmmm

Ukuran liyane sing kasedhiya ing panyuwunan.

Spesifikasi

| Spesifikasi - nulani kabel wire sawes | ||||

| Katrangan | filter | Struktur | Ketebalan | Porosity |

| μm | mm | % | ||

| SSM-P-1.5T | 2-100 | 60 + Lapisan Filter + 60 + 30 + + φ4x5px1.0T | 1.5 | 57 |

| SSM-P-2.0t | 2-100 | 30 + lapisan panyaring + + φ5x7px1.5t | 2 | 50 |

| SSM-P-2.5T | 20-100 | 60 + lapisan saringan + 60 + 30 + + φ4x5px1.5t | 2.5 | 35 |

| SSM-P-3.0T | 2-200 | 60 + lapisan saringan + 60 + 20 + + φ6x8px2.0t | 3 | 35 |

| SSM-P-4.0T | 2-200 | 30 + lapisan panyaring + + 20 + + φ8x10px2.5t | 4 | 50 |

| SSM-P-5.0t | 2-200 | 30 + lapisan panyaring + + 20 + 16 + 10 + 10 + + φ8x10px3.0T | 5 | 55 |

| SSM-P-6.0T | 2-250 | 30 + lapisan panyaring + + 20 + 16 + 10 + 10 + + φ8x10px4.0t | 6 | 50 |

| SSM-P-7.0T | 2-250 | 30 + lapisan panyaring + + 20 + 16 + 10 + + 10 + + φ8x10px5.0t | 7 | 50 |

| SSM-P-8.0T | 2-250 | 30 + lapisan panyaring + + 20 + 16 + 10 + 10 + + φ8x10px6.0t | 8 | 50 |

| Kekandelan saka piring piring bolong bisa disesuaikan miturut syarat pangguna. | ||||

Cathetan, yen digunakake ing pangatusan ngumbah macem-macem, struktur plato panyaring bisa dadi piring lima lan punching stander lan punching setin sepisan.

Yaiku 100 + lapisan panyaring + 100 + 12/44 + 12 + 12 + 4.0T (utawa piring ketebalan liyane)

Ketebalan piring piring piring uga gumantung karo panjaluk tekanan sampeyan.

Produk iki cocog kanggo lingkungan tekanan tinggi utawa permintaan mundur tekanan dhuwur, kanthi efektif ngatasi produksi industri farmasi lan kimia sing terus-terusan lan backwash online, syarat produksi steril.

Aplikasi

Pangan & Minuman, perawatan banyu, ngilangi bledug, apotek, bahan polimer, lsp.

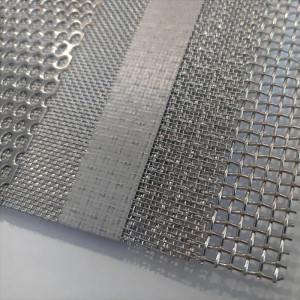

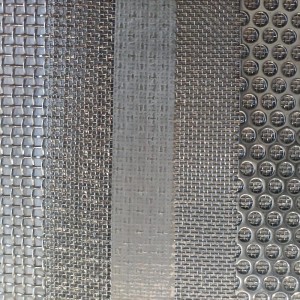

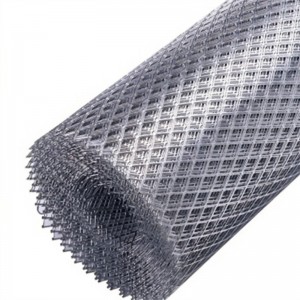

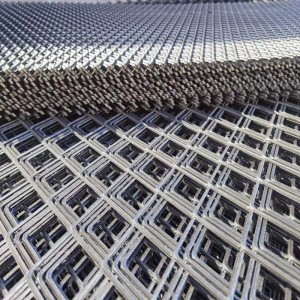

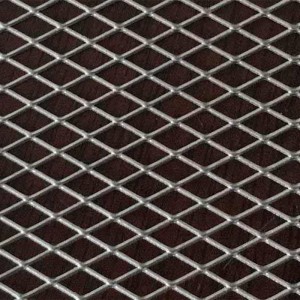

Plato plato perforated mesh minangka jinis filter sing kalebu bahan standar (stainless steel 304 utawa 316l) perforated pira perforated lan pirang-pirang lapisan bolong bolongan (utawa bolong sing kandhel). Plato punching bisa dipilih kanthi kekandelan beda miturut kebutuhan, lan net tenaga kosong bisa dadi siji utawa luwih lapisan. Amarga piring plate minangka dhukungan, bolong komposit duwe kekuwatan kompresif lan kekuatan mekanik. Sintering saka loro ora mung duwe permeelabilitas udara sing apik ing bolong, nanging uga duwe kekuwatan mekanik saka piring sing keros. Bisa diproses dadi cylindrical, disk, sheet lan cone saringan, digunakake ing perawatan banyu, minallurgy, industri bahan kimia, lsp.

Piring perforasi Mesh sing displorter wis digawe kanthi nyerat kerangka tekanan lan bolong panyaring menyang awak, saengga duwe karakteristik ing ngisor iki:

(1) kaku lan kekuatan mekanik sing apik. Amarga dhukungan plate Paulching, nduweni kekuwatan mekanik sing paling dhuwur lan kekuatan kompres ing antarane bolong sing sinyal;

(2) tliti filtrasi dhuwur, sawetara tliti filtrasi yaiku 1u-100u, lan nduweni kinerja filtrasi sing dipercaya;

(3) Gampang kanggo ngresiki, filter permukaan diadopsi, utamane cocog kanggo mundur;

(4) Ora gampang cacat, wujud bolong bolong tetep, ukuran celah seragam, lan ora ana bolongan buta. (5) Rintangan karat, resistensi suhu dhuwur, bisa tahan suhu 480 ° C.